Eyelet making tool

A brilliant idea by Scott Nicolich

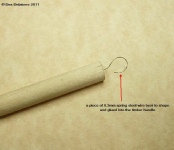

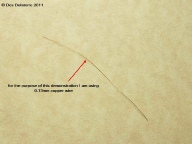

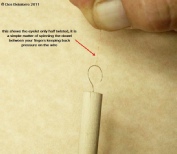

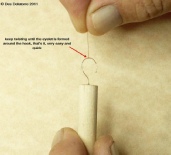

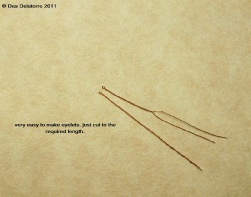

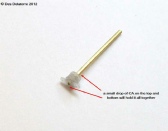

As you can see by the photos, simplicity is the name of the game. A piece of dowel cut to length, a small hole drilled in one end and a wire hook glued into the hole, that’s it. The sample sent to me by Scott had a hook made from 0.4mm wire, I like my eyelets to have a 0.3mm eye so I changed the wire.

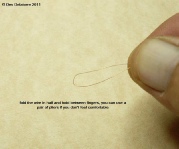

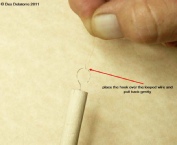

By following the instructions on each photo you will see how easy it is to make dozens of eyelets in a very short time and every eyelet will be exactly the same.

My thanks to Scott for sharing this idea with the rest of the modeling community and for sending me a sample to review, it is very much appreciated.

If you have any questions regarding this tool please feel free to contact me.

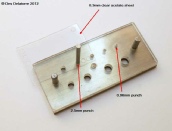

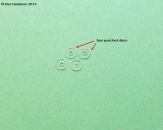

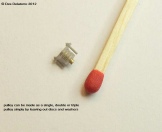

This method can be used to make single, double or triple pulleys very easily. I utilized my punch set to first punch a 0.96mm hole into a 0.3mm acetate sheet, this hole was then centralized over the 2.5mm punch, this was then punched to produce a disc, I need four of these to make a triple pulley.

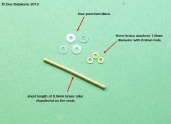

To give spacing between the discs and to create three separate pulleys, I used small brass washers 1.6mm in diameter with a 0.9mm hole. A short length of 0.9mm brass tube is needed for the axle, I chamfered the ends to make fitting of the washer easier. I also cut a top plate from 0.3mm acetate sheet and punched a 0.96 hole. I positioned a disc and the top plate over the axle and drilled two 0.4mm holes to take the two bolts, I also rounded the ends of the top plate.

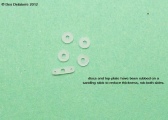

I reduced the thickness of the discs and the top plate by rubbing them on a sanding board, both side of the discs and plate need to be done. Assemble the pulley by firstly slipping a disc onto the axle, then a washer then another disc, this will give you one pulley. You could stop here and place the top plate on for a single pulley. For my purpose I need a triple pulley so I added another washer, disc, washer and disc then the top plate, this gives me a triple pulley. A small drop of CA at the top and bottom of the pulley on the axle will hold it all together.

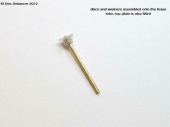

To simulate the holding down bolts I used Grandt Line bolts from their 5100 set. Once they have been glued in position I trimmed the length so they are level with the bottom disc. Cut the excess brass tube axle at the bottom of the pulley but leave about 1.0mm, this will give you a good mounting pin. Sand the top of the axle so it sits just a fraction above the top plate.

The last two photos show the completed triple pulley, this method is very easy and whether it be a single, double or triple pulley they all look very realistic once painted. I usually paint my pulleys with Mr Metal Color Stainless and give them a slight buff. Size comparison shows the pulley to be small, but they are not difficult to handle and assemble.